- English

- Search

- English

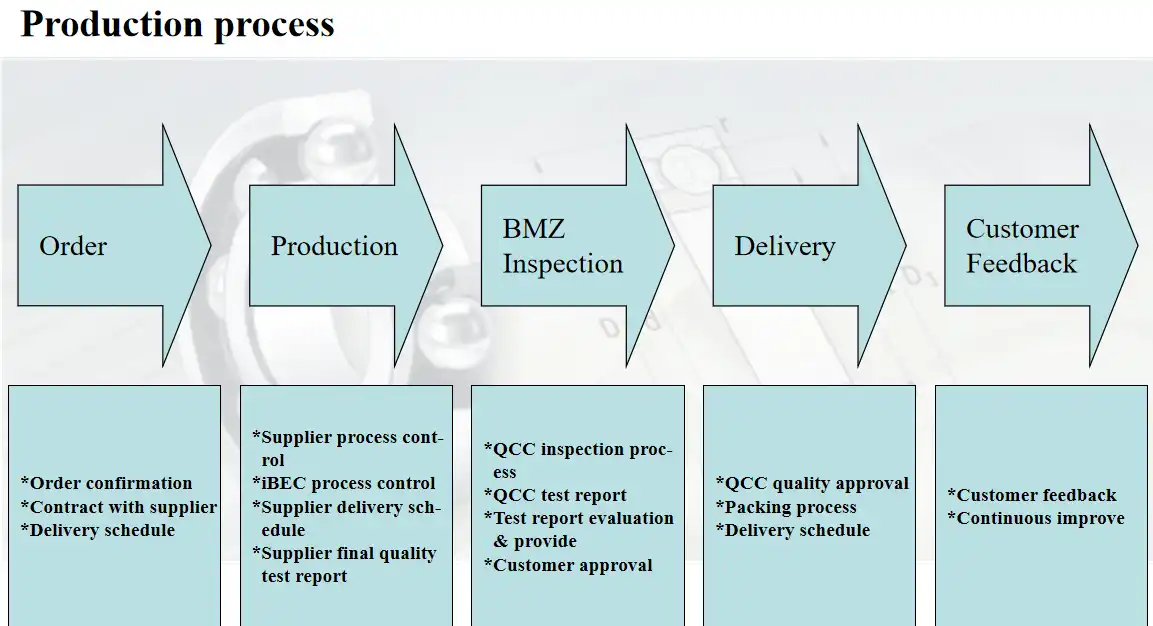

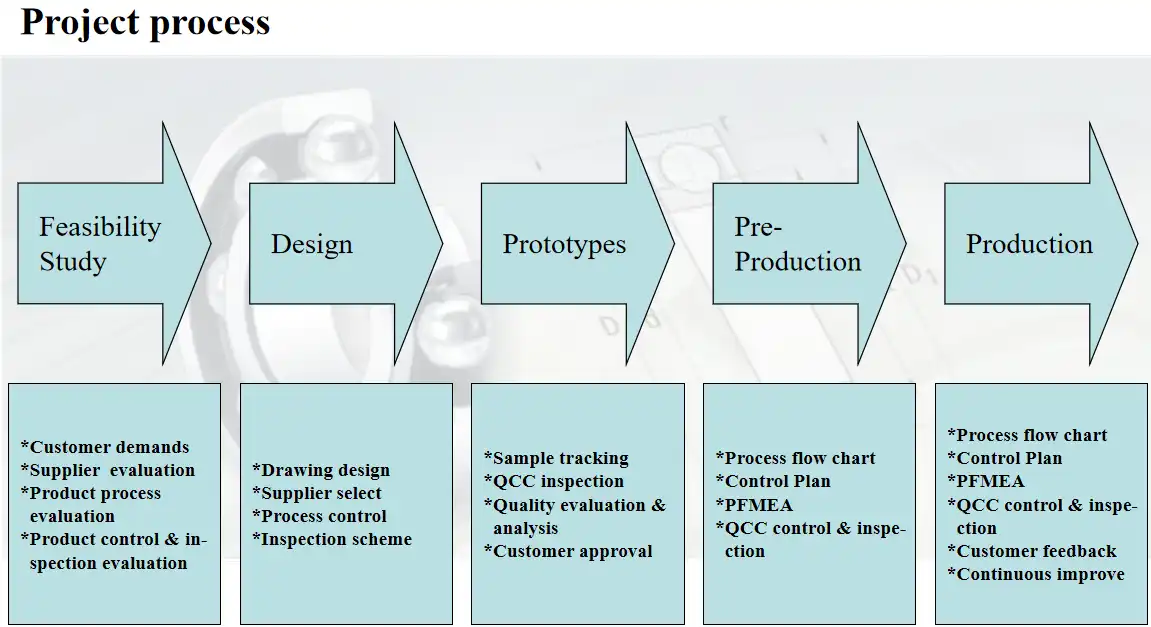

Project And Production Process

Five Steps To A Rewarding Bearing Solution

In order for the customer to obtain the optimal solution we work using a well documented proess in five steps. The process means that we can offer what you, the customer, needs for every bearing or application. We can often provide a solution which exceeds the function that you requested.

Feasibility Study

The requirement analysis is central to the feasibility study and is carried out in close collaboration with the customer and is documented to be the basis for the design phase of the project.

Design

With the starting point in the feasibility study,the need for version, material and precision is evaluated. This is documented in CAD designs with the aim of transferring to prototype manufacture.

Prototypes

The first examples of a possible end product are manufactured. They are measured and tested according to the specification which was agreed with the relevant customer.

Pre-production

When the prototypes are checked and approved the project moves to pre-production. Greater quantities are manufactured for quality assurance of the production process.

Production

Here the project moves to continuous delivery of quality assured production.

Application Adaptation

Through our refinement and installation of bearings in your application you achieve benefits in personnel costs as well as production speed. You achieve:

Faster and easier assembly

Faster and easier order handling thanks to fewer suppliers

Increased total precision

Optimized production planning and logistics

Lowest total cost

Greatest possible customer satisfaction

Accurate delivery

Long experience of china and established distribution channels contribute to accurate delivery. We offer direct delivery to you from china.