Ball bearings are a type of rolling bearing. Balls are installed between the inner steel ring and the outer steel ring and can withstand large loads. Also called ball bearings.

Ball bearings are mainly composed of four basic components: balls, inner rings, outer rings and retainers, also called cages or retainers. Ball bearings for general industrial use meet the AISI 52100 standard. The balls and rings are usually made of high-chromium steel, with a Rockwell C-scale hardness of approximately 61-65. The hardness of the cage is lower than that of the balls and rings, and its materials include metal (such as medium carbon steel, aluminum alloy) or non-metal (such as Teflon, PTEF, polymer materials). Ball bearings have smaller rotational friction resistance than journal bearings, so at the same rotational speed, the temperature generated by friction will be lower.

The purpose of a ball bearing is to determine the relative position of two parts (usually a shaft and a bearing seat) and ensure their free rotation, while transmitting the load between them. At high rotational speeds (such as in gyroscopic ball bearings), this use can be expanded to include free rotation with little wear in the bearing. To achieve this state, the two parts of the bearing can be separated by an adherent fluid film called an elastohydrodynamic lubrication film. Denhard (1966) pointed out that elasticity can be maintained not only when the bearing is subjected to the load on the shaft, but also when the bearing is preloaded so that the positioning accuracy and stability of the shaft do not exceed 1 microinch or 1 nanoinch. Hydrodynamic lubricating film .

Ball bearings are used in a variety of machines and equipment with rotating parts. Designers often have to decide whether ball bearings or fluid film bearings should be used in a specific application. The following characteristics make ball bearings more desirable than fluid film bearings in many situations:

1. The starting friction is small and the working friction is suitable.

2. Can withstand combined radial and axial loads.

3. Not sensitive to interruptions in lubrication.

4. There is no self-excited instability phenomenon.

5. Easy to start at low temperature.

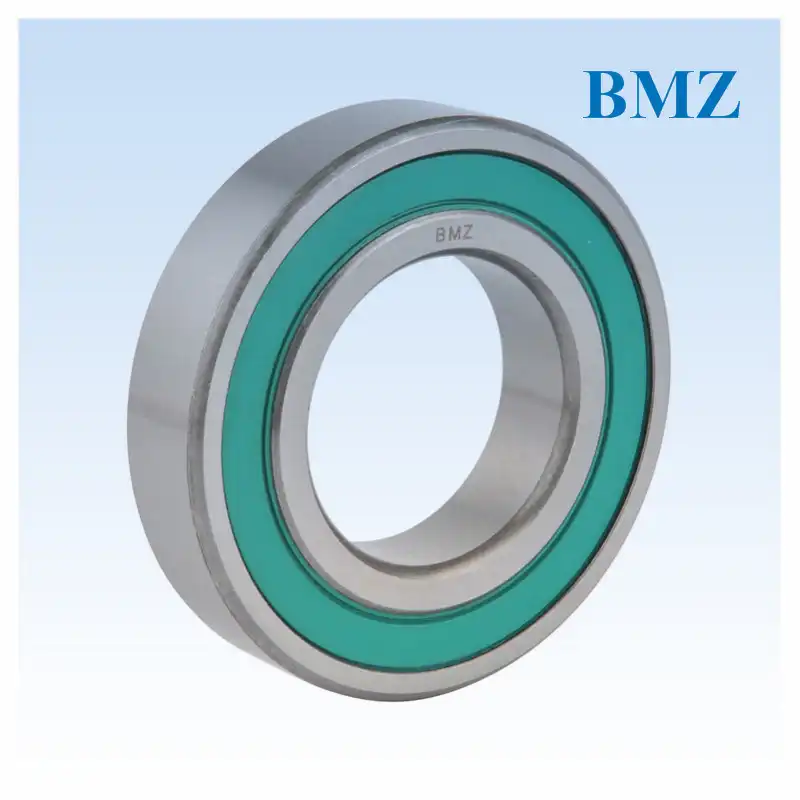

Deep Groove Ball Bearing 6000 series

1658 ZZ Bearing

1658 2RS Bearing

1658 Bearing

1657 ZZ Bearing

1657 2RS Bearing

1657 Bearing

1654 ZZ Bearing

1654 2RS Bearing

1654 Bearing

1652 ZZ Bearing